In the beginning, DEBATIN sold and processed paper. Then, in the 1920s and 30s, there was a sharp rise in paper consumption as industrialisation continued to spread, new technology developed and the advertising and packaging industries began to take shape. DEBATIN found itself perfectly positioned to cater to the increasing demand and establish itself on the market.

For many years, the factory in Bruchsal produced printed materials, paper sleeves, wax paper and paper bags (initially made by hand ). After the end of the 2nd World War, demand remained high for these products. Nonetheless, DEBATIN was eager to grow by expanding its portfolio and establishing itself in new markets.

Inventiveness, experience, new materials, new products – and new industries!

DEBATIN quickly turned its attention to plastic films, beginning with cellophane in 1953 and progressing to polyethylene in 1959. These films laid the foundation for a wide range of new products. Initially the focus was on using the new, robust films to produce “conventional” bags. Before long, however, intrepid inventors at DEBATIN began to experiment and develop new machines to produce the plastic shopping bags (highly modern at the time!) in Bruchsal.

It was this combination of experience and flexibility, scientific curiosity, inventiveness and a refusal to be daunted, that paved the way in 1973 for DEBATIN’s collaboration with Deutsche Bahn (UNIPACK® document pouches) and in 2002 to Deutsche Bank using DEBASAFE® safe bags for the introduction of the Euro.

1991 DEBASAFE security bags

Since then, DEBATIN has repeatedly drawn attention to itself with groundbreaking product developments. We’ve also gained a reputation for predicting market needs well in advance. To this day, we set standards in the industry – from the field of sustainability to our DEBAYOURS® project that offers personal, holistic support for all our customer’s packaging and logistics processes.

Today our products are used in the automotive industry and by banks, the police and online retailers. All of them rely on DEBATIN’s (tamper-evident and trackable) packaging to protect their products and deliver them safely – and increasingly sustainably – to their destination.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

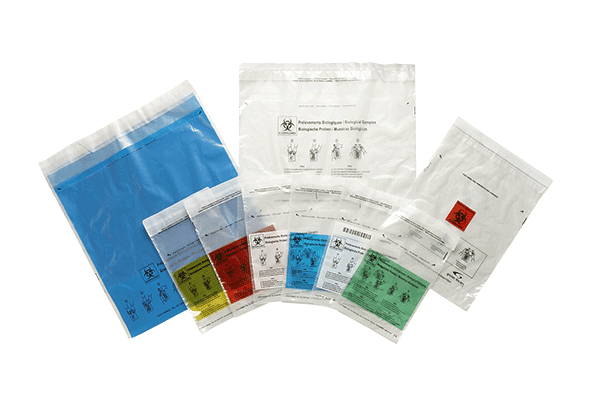

More InformationDEBAMED® products for diagnostic and medical samples in laboratories and hospitals

Hospitals and laboratories also rely on DEBATIN products when it comes to transporting diagnostic samples, medical samples and other content, safely and reliably. With DEBAMED®, DEBATIN has established a product range that caters to the highest safety demands as well as meeting all legal requirements in this sensitive area.

DEBATIN began developing and producing the DEBAMED® Speci-Bags range at its production sites in Hoenheim and Bruchsal in the early 2000s. Since then, DEBATIN has gained extensive experience and taken steps to ensure the continuation of the DEBAMED® success story: by collaborating closely with L.E.S.S. France, market leader in France for packaging and transporting biological samples (this culminated in 2019 in the acquisition of the company); by investing in additional specialised machines; and by focussing consistently on R&D. The portfolio now includes a wide range of products including secondary packaging such as DEBAMED® Speci-Bags 95kPa, various boxes for storage and transport, absorbers and bags that make life easier and safer for the people who work in laboratories and hospitals.

We’re already very excited about our newest addition to our DEBAMED® product family and look forward to presenting it to the world very soon – in our centenary year!